How are quickturn PCBs shipped to customers?

quickturn PCBs shipped to customers

The way your quickturn PCBs are shipped to you depends on the fabrication and assembly process. This is why it’s essential to choose a manufacturer who is highly experienced and has a track record of delivering high-quality products, meeting deadlines, and providing cost-effective services.

A well-established PCB manufacturer will have a dedicated team of trained and professional technicians that are able to speed up the process in a precise industry like PCB production. In addition to this, they will also have the latest equipment that is capable of cutting down on manufacturing time, resulting in faster and more efficient turnaround times.

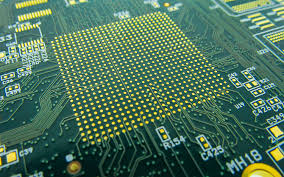

The first step in the quickturn pcb manufacturing process is computer aided design (CAD) that is used as the blueprint for the entire product. This is the basis for all the subsequent processes, including component placement, which can be single-sided or double-sided depending on your requirements.

How are quickturn PCBs shipped to customers?

After the CAD is complete, the board is transferred to the assembly department where it is made into a functional product. The components are fitted onto the board by hand or by using automated machines, depending on your needs and the complexity of the board. Once the board is finished, it is inspected by an experienced quality assurance team to ensure that it meets all the required specifications.

During this stage, any design flaws can be corrected, leading to a better-quality end-product that is free from defects and errors. It also allows the client to make changes before the fabrication process is completed, which is a great advantage as it can save time and money.

Once the PCB is completely assembled and tested, it will be ready to ship. This can be done via air, air/sea combined, or sea depending on your specific requirements and urgency. A good PCB manufacturer will be able to advise you on the best shipping options based on your specific situation.

When choosing a PCB manufacturer, make sure that they follow a stringent quality control system and abide by the relevant codes and standards such as ISO, RoHS, UL, and Reach. They should also have a strong reputation in the market for delivering quick-turn prototypes, beta builds, and pre-production units to clients on time. Moreover, they should be flexible enough to accommodate any changes or new designs that may arise during the process. This will ensure that your quick-turn project is always delivered in a timely manner.